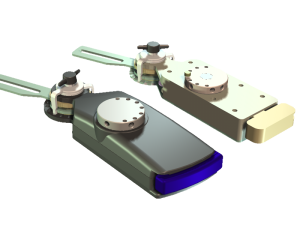

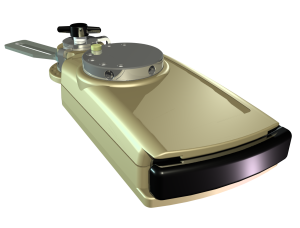

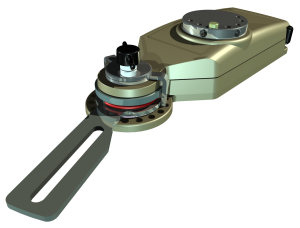

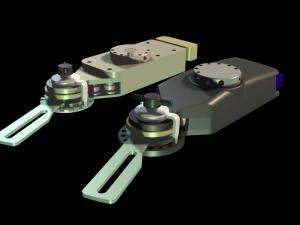

The DeRoyal DeROM, also formerly known as the SP-Hinge.

Originally the customer was LMB Hand Rehab, of San Luis Obispo, California, which was acquired by DeRoyal Industries during the duration of this project. This was our second project for this customer.

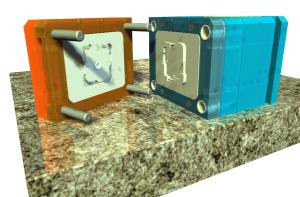

The job entailed a complete redesign of the product, transitioning it from a CNC aluminum assembly into a plastic injection molded assembly.

We accomplished the preliminary design and pre-sale concept description using AutoCAD R14 (for DOS—the AutoCAD for Windows just never did it for me).

- On all projects prior to this, we generated G-code files (for CNC machining) using a combination of manual CNC programming and output generated by a program we wrote in Turbo Pascal. This program converted toolpaths drawn in AutoCAD into G-code by reading the DXF output that included AutoCAD Blocks containing depth of cut strategies. The program could also read 3D polylines to do full 3-axis milling.

But for this project's final design and mold tooling design we now had IronCAD 3D solid modeling at our disposal, which really made this project a joy, as well as allowing us to produce a very nice product.

Perideo's new design resulted in

- a reduction in assembly piece-count, and

- a marked reduction in production cost overall.

We believe the tooling paid for itself in the first year of production.